Our Team

NICHOLAS JACOBSON, Co-Founder and CTO

Nicholas Jacobson is an architect, scientist, engineer, and inventor whose work focuses on integrative design across scales, disciplines, and technologies. His practice centers on transforming complex systems and data into tangible, functional outcomes through advanced modeling and fabrication. Trained as both an architect and artist, he approaches innovation by first understanding context, constraints, and performance, allowing form and aesthetics to emerge from integrated structure, material, and program rather than stylistic intent. His work spans scientific research, advanced manufacturing, and experimental fabrication, with projects published and exhibited nationally and internationally. Alongside his technical practice, he maintains an artistic practice rooted in the byproducts of experimentation, using these artifacts to reveal new insights and unintended applications. He has a Bachelor’s of Architecture from the University of Wisconsin and a Master’s of Design Technology from Harvard University in the Graduate School of Design.

JORDAN LEWIS, Co-Founder and CEO

Jordan Lewis is a veterinarian and entrepreneur who has focused on startups within the life sciences. Skilled at integrating medical knowledge with business innovation, he has successfully navigated complex multi-disciplinary regulatory frameworks while pioneering new business ventures. His experience spans the full life cycle of startups: from inception, fundraising, execution to operations. He received his Veterinary Medical Degree (VMD) in Medicine and Surgery from the University of Pennsylvania in 2008.

Nick and Jordan have been working together since 2016. They met after Jordan read an article about Nick’s recent project featured in Vogue. Jordan hired Nick and his team to consult on numerous projects for his companies.

ROB DUCEY, Co-Founder

A failed professional soccer player, I have over 25 years of experience working in visual effects and animation. My career started in scientific visualization and entertainment production at a small company in Ames, Iowa. This led to an opportunity as a technical director and visual effects artist at Big Idea Productions in Chicago, known for their popular series, VeggieTales. Nearly twenty years ago I left that studio for Vinton in the rainy Pacific Northwest, a commercial production studio at the time most identified with the California Raisins and the iconic M&M's characters. I first became acquainted with 3D printing when the Knight family rebranded the studio LAIKA and began production on Coraline, our first feature film. On that production, we pioneered the use of 3D printers to produce the facial animation for the main characters, generating thousands of parts for a technique known as replacement animation. On every subsequent film I have been involved in the further development and expansion of that process which was received a Scientific and Engineering Award from the Academy of Motion Pictures Arts and Sciences in 2016. Today I am the technical supervisor for the Rapid Prototyping department, responsible for integrating additive manufacturing technology with many of our production processes as we work on our sixth feature, Wildwood. Additionally, I support Nick and his team at InWorks to apply my knowledge of digital design and additive manufacturing on their many projects. I am a member of AMPAS, VES, and ASIFA.

Selected Publications

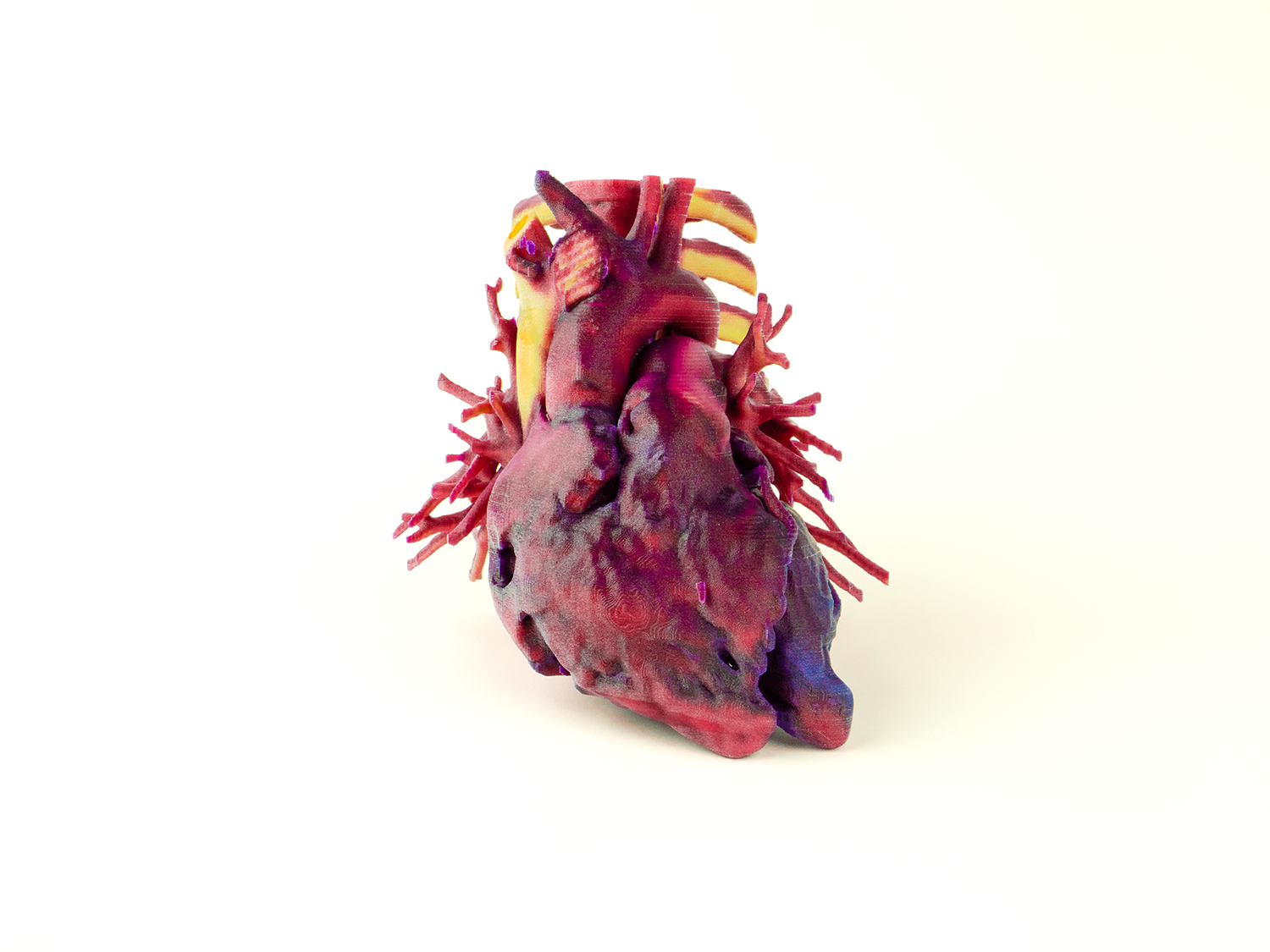

The Inner Complexities of Multi-modal Medical Data: Bitmap-based 3D Printing for Surgical Planning Using Dynamic Physiology. 3D Printing and Additive Manufacturing. Authors: Jacobson, N.M., Brusilovsky,J., Ducey, R., N. V. Stence, A. J. Barker, M. B. Mitchell, L. Smith, J. C. Weaver. (2023)

Voxel Printing Anatomy: Design and Fabrication of Realistic, Presurgical Planning Models through Bitmap Printing. J. Vis. Exp., e63214, In-press (2021). Authors: Jacobson, N. M., Smith, L., Brusilovsky, J., Carrera, E., McClain, H., MacCurdy, R.

Defining Soft Tissue: Bitmap Printing of Soft Tissue for Surgical Planning. 3D Printing and Additive Manufacturing. Authors: Jacobson, N. M., Smith, L., Sheridan, A, Stence, N., J., Carrera, E., Browne, L., MacCurdy, R. 28 Apr 2022

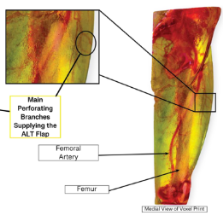

Hybrid modeling techniques for 3D printed deep inferior epigastric perforator flap models 3D Printing in Medicine, In-press (2023). Authors: Jacobson, N. M., Carrera, E., Treat, A., McDonnell, M,. Mathes, D., Kaoutzanis, C.

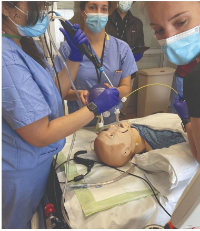

Digital workflow for high-risk, low-volume procedure simulation. Journal of Biomed Research. Authors: Jacobson, N. McClain, H., New, M. Mar 2022

Contingency planning for healthcare worker masks in case of medical supply chain failure: Lessons learned in novel mask manufacturing from COVID-19 Pandemic. Authors: Cumbler E, Wittig M, Jacobson N, McClain H, Treat A, Radin J, Stowell S, Harry E. American Journal of Infection Contol, 08/03/2021

Rapid Prototyping Airway and Vascular Models from 3D Rotational Angiography: Beans to Cup 3D Printing. Authors: JE Zablah, SA Rodriguez, N Jacobson, GJ Morgan Progress in Pediatric Cardiology, 101350. 2021

Computational Design in Creative Industries in: “CODIFY Computation in Landscape Architecture”. Authors: Friedman, J. Jacobson, N. Cantrell, B. Mekies, A. Routledge 2018

Voxel Beam: Topology Optimization for Mulit-Material 3D Printing. Authors: Hosny,A., N Jacobson, Seibold, Z. CAADRIA. 2015 & GSD Platform. 2014

3D printing for an anterolateral thigh phalloplasty 3D Printing in Medicine, In-press (2023). Authors: Walker, M., Kaoutzanis,C., Jacobson, N. M.

Awards

Liver Long and Prosper Journal of Anatomy, In-Review (2024). Authors: Kim, A., Jacobson, N. M.

Face Fixin' Journal of Anatomy, In-Review (2024). Authors: Tripp, K., Jacobson, N. M.

2024 Anschutz Accelerator Initiative

Co-Investigator $6,000,000

2023 Children’s Hospital Innovation Grant - Digital Nasoalveolar Molding

Principle Investigator $25,000

2022 State of Colorado Advanced Industries Grant - Digital Nasoalveolar Molding

Principle Investigator $150,000

2022 Align Technology Research Award - Digital Nasoalveolar Molding

Principle Investigator $25,000

2021 Smile Train Grant - Digital Nasoalveolar Molding

Co-Principle Investigator $10,000

2020 AB Nexus Award - 3D Printing for Presurgical Planning.

Co-Principle Investigator: $50,000

2022 Gates Grubstake Award - 3D Printed Implantable Devices.

Principle Investigator $350,000

2021 VA Hospital - Patient-Specific 3D Printed Bronchoscopy Trainer

Principle Investigator $25,000

2021 OEDIT Award State of Colorado Advanced Industries Grant.

Principle Investigator $130,000

2020 AB Nexus Award - 3D Printing for Presurgical Planning

Co-Principle Investigator : $50,000

2017 International Federation of Landscape Architects IFLA AAPME

National Award of Excellence